PROJECT DETAILS

Place of Application: Oil Field Zdanice

Cleaning Technology: Perforation cleaning with „DIR-X“

5 – 15 Wells were cleaned between 2002 and 2021, annually.

Well Parameters

Well depth 1000 m, reservoir temperature 29°C

The well lost production due to asphaltene / paraffin deposits in the perforation. Standard cleaning method: pull the sucker rod pump and tubing out of the hole, cleaning with steam from paraffin / asphaltene at the surface, casing cleaning with scraper and hot oiling. Production rate after standard paraffin treatment was very low to zero. Perforation was still damaged by asphaltene / paraffin deposits.

Cleaning Process – Heating up the perforation

Mixture quantity: 2.4 m3

Cleaning time: up to 3 hours

After cleaning the casing with scraper, overheat the perforation by use of DIR-X.

Process:

- raise the scraper up above the perforation

- pump the DIR-X into the perforation (not into the reservoir) down the tubing

- after the reaction break (half an hour), wash the spent DIR-X along with melted asphaltene / paraffin deposits out of the well

- complete the well with clean subsurface equipment

- restart oil production

Result of Cleaning

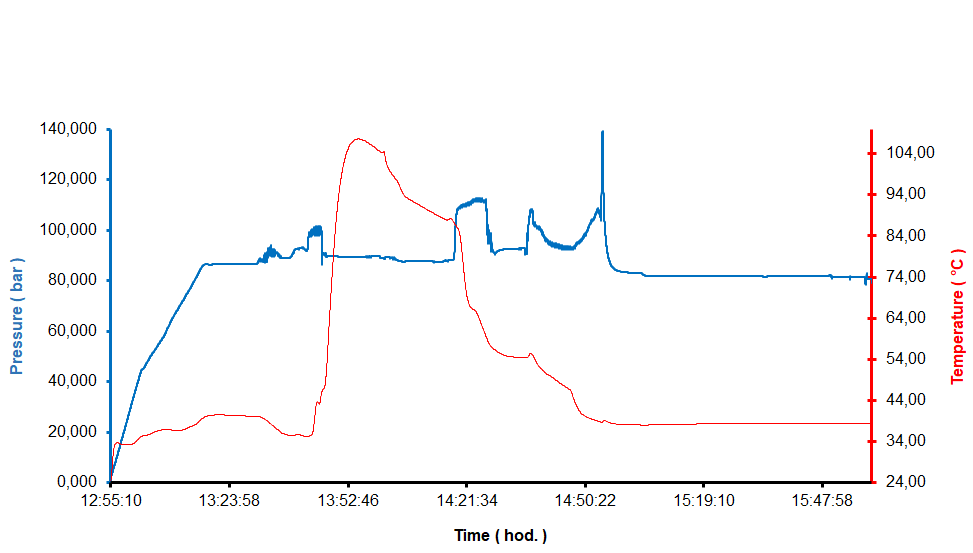

After perforation cleaning with DIR-X well production was restored to expected capacity and reached normal operating conditions in very short time and with lower costs. Measured and documented level of temperature and time of over 80°C with DIR-X application: more than 20 minutes.

Figure 1 Graph of pressure and temperature in cleaning time. Temperatures were measured via downhole temperature gauge placed in the perforation.